A cutting-edge 3D weaving loom that is the only one of its kind in the UK is at the heart of a new £1.75 million textiles innovation centre at the University of Leeds.

The centre, which will develop advanced prototypes for a wide range of sectors, from aerospace to healthcare, is part of a wider investment in facilities at the University’s School of Design, cementing its place at the leading edge of both technical research and creativity.

As part of the £4.4 million upgrade, new weaving, knitting, digital printing, coloration and colour communication facilities have enhanced the School’s world-beating research and development capabilities.

From 3D weaving to innovative inks and digital printing, from innovation in colour imaging and lighting, to increasing sustainability in clothing, the year-long programme has also provided new laboratories, exhibition areas and student spaces.

Many of the improvements have taken place in the School’s Clothworkers’ South Building, opened as the Man-Made Fibres Building in 1956, which has long been home to major innovations in fabrics, colour science and printing – reflecting Yorkshire’s rich textiles heritage.

“The new equipment and facilities we are unveiling are a key part of the University’s aim to invest in knowledge and opportunity.”

Professor Chris Carr, Head of the School of Design, said: “The new equipment and facilities are a key part of the University’s aim to invest in knowledge and opportunity – to provide the very best for our researchers and students and to enhance the excellent partnerships we have with the very best designers and industrialists across the region and indeed the world.

“Our investment will also help us continue to enhance productive relationships between design and technology.”

The 3D Weaving Innovation Centre is part-funded through a £881,191 grant from the European Regional Development Fund (ERDF). It places the School at the forefront of 3D weaving technology, design and production. Multi-layer, multi-level wovens will be developed by the centre’s team alongside textile manufacturers.

Roger Marsh OBE is Chair of Leeds City Region Enterprise Partnership (LEP) and ESIF sub-committee, which provided strategic oversight for the ERDF funding for the 3D Weaving Innovation Centre.

He said: “Innovation is part of the fabric of Leeds City Region and its textile industry, in particular, is central to our innovation pedigree.

Mr Marsh, who is also an alumnus of the University and a member of its Council, added: “We’ve proven ourselves to be an unrivalled hub of pioneers and innovators throughout our history, and I’m confident the 3D Weaving Innovation Centre will add even more value to our already enviable heritage.”

Dominic Dormeuil is President of luxury textiles firm Dormeuil, which is based in Paris and London but has a commercial base in Dewsbury and a long-term partnership with weavers in Yorkshire. Its fabrics have clothed the well-dressed and famous for decades – from The Beatles to James Bond, from politicians to royalty.

Another Leeds alumnus, he spoke warmly of his time at the University studying Textile Management almost 40 years ago.

“I am a firm believer that strong cooperation between universities and companies is key to the successful research of new innovative processes and products," he said.

“Dormeuil are now looking to work with the School in developing new products and introduce innovations in to the fabrics that will be world beaters and leaders to be showcased around the world.”

Researchers in the School representing a wide range of disciplines work with household names such as Unilever, Adidas, L’Oréal, the National Portrait Gallery and Dyson.

After a formal ribbon cutting to open the new building, visitors – with leading industrialists from the textile and design sectors and alumni among them – will be given tours of the building with its new equipment and facilities, demonstrated by staff and students.

Leading edge of design and manufacturing

The new equipment in the School includes:

- In the 3D Weaving Innovation Centre – a MAGEBA multi-shuttle loom (with four shuttles, instead of the usual one), coupled to a computer-controlled Staubli Unival harness, provides the technological platform to design and produce innovative, seamless multi-layer fabric structures;

- The Centre’s knitting area features two Shima Seiki knitting machines – one a whole-garment manufacturing system that makes garments without seams or stitched panels, complete with integrated buttonholes and pockets. Research into 3D knitted structures is particularly important in the areas of sportswear and healthcare materials, such as compression bandages;

- Unique in the UK, LED lighting is used to evaluate different kinds of light in relation to human perception of colour – for example for use in art galleries to establish the optimum lighting for paintings. An eye tracking system will be used for research into consumer behaviour – for example how people view store displays and web pages. Both systems can be linked to brain monitors. The lab will also be used to examine the effects on health and sleep of different lighting and – for example – tablet computers and smartphones;

- In the School’s digital printing laboratory are a range of printers used for applying reactive dyes to cotton, dye-sublimation inks to polyester and latex inks to textiles and films. In addition, there is a full-width calendar for sublimation printing on polyester fabric, a garment printer using pigment inks and a 3D printer for a wide range of materials including textiles, film, paper, and even mobile phone covers. It is a truly comprehensive creative application lab for designers;

- In a materials printing lab, a Dimatix materials printer will allow for custom-developed inks for creative effects and surface engineering for functionality;

- A colour imaging lab allows for colour analysis using calibrated cameras and light boxes, this has uses as varied as cosmetics, teeth, food and textiles;

- A fabric testing lab features the latest textiles analysis equipment, funded partly by alumni Linda and David Repper, former owners of the Halifax firm which makes the equipment, James Heal. The lab facility characterises the full gamut of textile properties ranging from wet abrasion, ‘feel’, moisture transfer, drape and strength;

- For nonwoven fabrics – familiar in the form of wipes and surgical dressings – an electrospinner and centrifugal force spinner produce nanofibers for biomaterials, healthcare and filtration media;

- Other equipment in the School includes colouration and effect chemistry applicators; dyeing machines; atmospheric plasma technology for surface modification and engineering; flammability testing machinery and melt and wet fibre spinners. Super critical carbon dioxide dyeing and extraction systems provide the platform for research into environmentally-friendly textile processing.

Further information

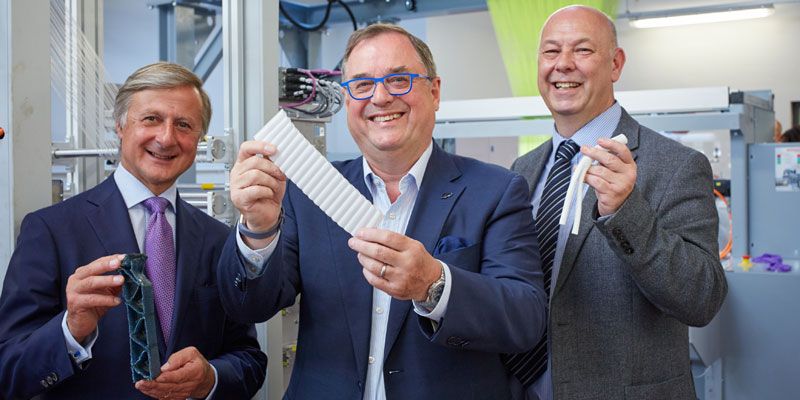

Main images shows, from left, Dominic Dormeuil, Roger Marsh and Professor Chris Carr in the 3D Weaving Innovation Centre, with some of the engineering and clinical prototypes it is capable of producing.

For enquiries about the 3D Weaving Innovation Centre, contact Caroline Rose, Project Manager, on +44(0)113 3433777 or email c.m.rose@leeds.ac.uk.

For interviews and images, contact Media Relations Manager Gareth Dant in the University of Leeds press office on +44(0)113 343 4031 or email g.j.dant@leeds.ac.uk

The School of Design at Leeds has a long and distinguished history with its roots going back to 1874. Since then it has established a reputation as one of the world’s leading textile centres. Its core focus has expanded to include graphic design, fashion design, contemporary art practice and design, and materials technology.

Design, colour, textile materials and sustainability are key elements in the ongoing success of the School, supported in part by the generosity of the Worshipful Company of Clothworkers of the City of London - the School’s main building was erected by the Clothworkers and was one of the earliest on the University campus.

The Leeds City Region Enterprise Partnership works with the West Yorkshire Combined Authority to help businesses in our region grow and become more productive.

The Combined Authority works in partnership with local councils and businesses to ensure that everyone in our region benefits from a strong, successful economy and a modern, accessible transport network. By championing the region’s interests nationally and internationally, we secure the investment to deliver better transport and housing, help businesses to grow and create jobs.

We want our region to be recognised globally as a strong, successful economy where everyone can build great businesses, careers and lives.

For more information visit www.westyorks-ca.gov.uk.

European Structural and Investment Funds – 3D Weaving Innovation Centre

The project received £881,191 of funding from the England European Structural and Investment Funds Growth Programme 2014-2020. The Ministry of Communities and Local Government and the Department for Work and Pensions are the Managing Authorities for European Regional Development Fund and European Social Fund funding through the Growth Programme, funds established by the European Union to help local areas stimulate their economic development. By investing in projects the funds will help to support innovation, businesses, skills and employment to improve local growth and create jobs. For more information visit https://www.gov.uk/european-growth-funding.