Energy sciences and engineering

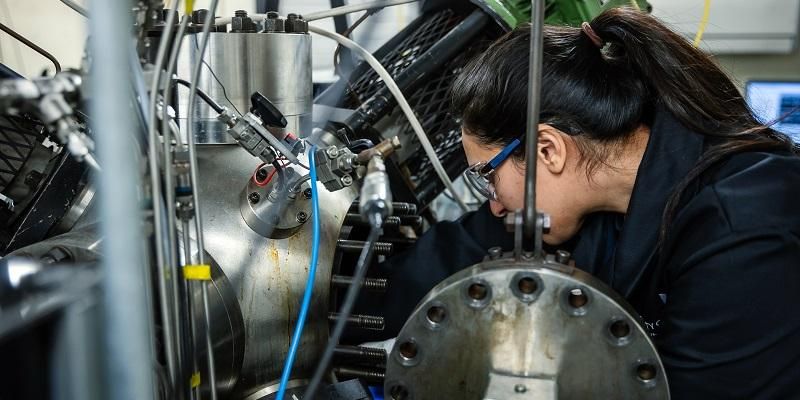

The University of Leeds undertakes an extensive range of engineering and scientific research and many aspects of this work are helping to develop new energy solutions or improve the efficiency of existing technologies.

Expertise in geosciences, fluid dynamics, surface engineering and tribology is being used to tackle diverse energy challenges in geothermal energy, subsurface storage for carbon dioxide or nuclear waste, battery technologies, next generation nuclear reactors and solar power.

Geosciences

Our geoscientists have worked for many decades supporting exploitation of hydrocarbon reservoirs, and this expertise in geological characterisation and subsurface modelling is now being applied to explore the potential that the subsurface has to offer to influence future energy generation, storage and consumption.

This includes:

- Sedimentology, structural geology, geophysics, engineering geology and basin analysis enabling accurate reservoir characterisation, for geothermal, CO2 storage, nuclear waste storage, and energy storage.

- Hydrogeology and geochemical research providing expertise in groundwater flow, chemistry and composition and thermal properties of the rock or soil for geothermal systems or heat storage.

- Petrophysics, with particular expertise in low permeability rocks and faults.

- Geotechnical engineering expertise allowing the strict geo-mechanical planning and monitoring for use of lined rock caverns for energy storage.

- Innovative seismic monitoring research, including using satellite observations to interpret seismic waves in the subsurface that might indicate leakage from subsurface reservoirs.

Our laboratory and research facilities are amongst the best in the world, including:

- Wolfson Multiphase Flow Laboratory

- Sorby Environmental Fluid Dynamics Laboratory

- Rock Mechanics, Engineering Geology and Geotechnical Laboratories

Surface engineering, tribology and corrosion

The formation of unwanted minerals on surfaces – such as carbonates, sulphates, and sulphides – impedes the operation of many industrial processes, including oil and gas production and geothermal plants. Our researchers use specialist optical microscopy to assess this scaling process in-situ and in real time in the laboratory, allowing them to develop accurate models that can be applied across a range of contexts.

The University has dedicated equipment able to test materials in highly corrosive molten salt environments, and we are developing assessment tools for conventional and next generation corrosion resistant alloys. These will be critical for next generation molten salt nuclear reactors and to increase efficiency of solar power plants, where molten salt is used as a heat transfer fluid and for thermal energy storage.

Our skills in electrochemical corrosion and in advanced surface analysis are also supporting battery research, developing new electrode materials and helping to improve efficiency and longevity through understanding and engineering the films and layers that build on the electrode surface.

Fluid dynamics

We draw on our expertise in fluid dynamics to better understand the behaviour of nuclear waste sludge materials, drawing on both experimental research and modelling.

Using a range of techniques, including ultrasound, we characterise the particle shapes and sizes within sludge, and assess how the sludge behaviour will change under different conditions, such as turbulence, gravity, settling, agglomeration and particle break up.

The aim of this research is to develop a validated predictive model for how sludge will behave within closed pipes, to help design more efficient and safer waste treatment processes.

Work with us

For enquiries about working with us on energy sciences and engineering please email the Energy Leeds team via energy@leeds.ac.uk.